[/vc_column][/vc_row]

What we do at SS Metals & Industries?

Our Fabrication Services

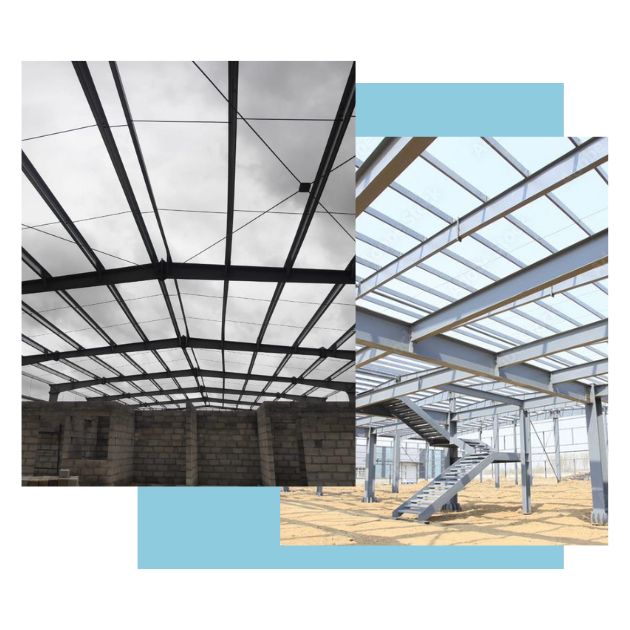

PEB

High Rise PEB Construction

With continuous development and improvisation of processes comes efficiency, and cost effectiveness. When it comes to building structure construction PEB is the way to go. PEB has revolutionized the way buildings are thought and built. They are cost effective, require less time to build and are modular.

![]()

Our Services

A tank truck or tanker truck or tanker is a motor vehicle designed to carry liquified loads, dry bulk cargo or gases on roads.

PRE-CLEANING

Pre-Rinse

Extra Flush

Pre-Steam Internal

RESIDUAL HEEL HANDLING AND DISPOSAL

Contaminated Rinsate or

Condensate

Non-Haz. Liq. Or Solid

Hazardous Liquids

Listed/Reactive Waste

INTERIOR CLEANING

Pre-Solve Application

Water Flush Only (No Dry, No Hoses)

Water Wash

Water Flush & Steam

Detergent Wash

Caustic Wash

Boosted Caustic Wash

Petro-Detergent Wash

Petro-Caustic Wash

Diesel Flush

Stripper Wash

CUSTOM SERVICES

Hose Clean

Hose Clean w/o Interior Clean

Pump Clean with Interior Clean

Pump Clean w/o Interior Clean

Dry Only

Special Handling

Steam Coils

Exterior Trailer with or w/o Interior Clean

Deodorize

Vacuum Check

Hand Labor

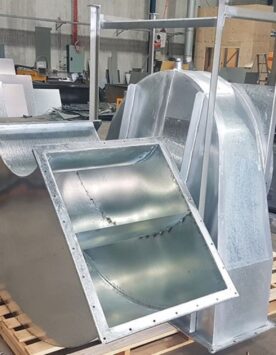

Whether you need a single specialty item, a piece of equipment made right away, or a large-scale production run completed in a matter of weeks, you will need efficient and affordable sheet metal fabrication.

SS Metals uses the latest equipment and technology, enabling them to take your plans and produce the sheet metal fabrication product to your requirements you need in a timely manner, on a budget, and with no waste. We have vast knowledge and experience bending, forming, and working with sheet metal fabrication. We approach our fabrication projects with focused attention on details and superior customer service.

Reducing Your Sheet Metal Fabrication Timelines

Sheet metal fabrication is just one part of the diverse metal fabrication services we offer at SS Metals & Industries. We realized that when an order for a sheet metal project came in, there were other services that customers need to assemble and create their project.

By keeping your sheet metal fabrication project with one fabricator, you can reduce and minimize any shipping delays or errors between subcontractors.

Sheet Metal Fabrication Projects

Sheet metal can be bent, punched, cut, rolled, and stamped within SS Metals in House plant. Some projects that may use sheet metal might include:

- Doors

- Enclosures

- Body Panels

- Brackets

- Cones

- Bins

- Industrial Ductwork

High Production Volume For Sheet Metal Fabrication

There are times when you will require a very large production volume to fulfill your work order and maximize your profitability. SS Metals & industries is capable of producing thousands of units with reasonably short lead times and uses the latest technology.

Our Campbellfield, Melbourne road tanker service center, specialises in chemical, milk, fuel, bitumen, food grade and dry bulk repairs. Factory trained technicians, with strong diagnostic skills are available for a range of service offerings including –

- Minor & Major Repairs

- Major Rollovers and Upgrades

- Refurbishments

- Hydrostatic Testing

- Safe Load Pass Inspections

- Engineering expertise

- New Decoking facilities for all Bitumen tankers

- Insurance claims

Intermediate bulk containers are reusable, multi-use industrial-grade containers engineered for the mass handling

We are able to clean both Rigid and Flexible IBC containers.

INTERIOR CLEANING

Water Wash

Water Flush & Steam

Steam, Rinse & Vapor Scrub

Detergent Wash

Caustic Wash

Petro-Detergent Wash

Petro-Caustic Wash

Boosted Caustic Wash

Special Wash

Food Grade Wash

RESIDUAL HEEL HANDLING AND DISPOSAL

Non-Haz. Liq. Or Solid

Hazardous Liquids

ENVIRONMENTAL SRV

Vapor Scrubbing

Passivation

SPECIALTY SERVICES

Haz Waste Repackaging

High Haz Chemical Cleaning

Pre-Engineered buildings or PEBs structure are made up of various components that give them their unique properties and make them sturdy and durable. Pre-Engineered Buildings are known for their flexible design, high structural strength and ease of construction. But all this is made possible due to the various components that go into building a PEB. Just like any assembled structure, a PEB consists of components that can be categorized into 3 main types and a few accessories.

A PEBs Structure (Pre-Engineered buildings) is made of:

Primary Components

Secondary Components

Roofing or Cladding

Other Accessories

#1 – Primary Components:

The Primary components include 3 main parts: Main Frame, Columns and Rafters.

Main Frame:

The main frame is the basic structure of the building which is made of rigid steel. It is built using tapered columns and rafters, sometimes also referred to as built-up members. There are spliced plates welded to the end of these tapered sections. The splice plates of connecting sections are bolted and the frame is erected.

Columns:

Columns are used to transfer the vertical load to the foundations. These are generally made up of I sections which give benefits in terms of strength while being economical to produce.

Rafters:

Rafters are sloped structural members or beams that extend from the ridge or up-to-the wall-plate.They are designed to support the roof deck and other loads associated with it.

#2 – Secondary Components:

Purlins, Bracings, Tie rods, Angle bracings, High Tensile Bolts and washers etc. are classified as secondary components that are used in a PEB. These parts are used to support walls and roof panels. In addition to that, the secondary members also help the building withstand the longitudinal loads that the building may see during earthquakes and heavy winds. Purlins are mostly unique cold roll-formed sections used to fix roof and side claddings. They are available in different variations such as Z, C and Sigma purlins which are denoted by their cross-section.

#3 – Roofing or Cladding:

Roofing sheets, as their name suggests,provide protection to the building interior from the environment. They can be designed to either block sunlight or allow partial sunlight to illuminate the interiors, depending on the requirement. A Standard supply of material for Roof Sheets is 0.47 mm Bare Galvalume and for wall Claddings it is 0.50mm Colour coated Galvalume.

#4 – Other Accessories:

Several accessories are available for Pre-Engineered Buildings or PEBs structure that can greatly increase the functionality of the building. Depending on the type of application, the accessories may be selected. Some of the many available accessories used in PEBs are

Windows

Turbo Ventilators

Louvres

Sliding Doors

Roll-Up Shutters

Skylight Sheets

Ventilators

Downspouts

Product Container Cleaning Services

01

High Pressure Automated Cleaning System

It is a high-pressure cleaning equipment with 360 spinning heads and facilities for Hot, Cold, Steam and Detergent Injection from a common delivery point. We use a high-grade vacuum system to clear all the moistures. Scrapping, Buffing & Mopping are the few operations carried out at the end.

02

A Clean, Safe, Community is Good Business.

A complete one-stop solution for the cleaning / repairing of ISO tanks, Dry containers as well as Road tankers including storage of ISO Tanks and Dry Containers. M/s S.S. Metals & Industries has responded to the demands of the customers for a convenient and quick repair option located within our Facility. Expanding our maintenance network reduces the downtime of the Product Carriers.

03

Recycling & Safe Disposal of Industrial Waste

All the water used for the Road Tankers / ISO Tanks / Dry Containers cleaning purpose are treated by our Semi-Automatic Effluent Treatment plant (ETP) to meet the Karnataka State Pollution Control Board (KSPCB) norms. Utilizing a heels management program which returns heel to the customer as a product or is reused by the facility for Washing. We as a company protect our environment, our customers, and the business by being Environment-Friend.

![]()

Organizations we Worked With

pin-up casino

Plinko casino

1win casino

pin up casino AZ

Mostbet UZ da jonli kazino o’yinlari va sport tikishlari bilan vaqtni o’zgacha o’tkazing.

Die perfekte Wahl für Spielfans: plinko!

Mostbet casino

Vous trouverez des jeux de table, des machines à sous et plus encore dans les meilleurs casinos en ligne.

Güvenli altyapısıyla Aviator indir, kişisel verilerinizi korur.

Test din strategi på glitchspin og udfordre dit held!

1xbet يتميز بسرعة السحب والإيداع.

Mostbet casino

Tipps für verantwortungsvolles Spiel in jedem casino ohne oasis.

Die beste wetten ohne oasis bieten faire Quoten und schnelle Gewinne. Das sorgt für Begeisterung.

Non preoccuparti dei pagamenti, prova i casino non AAMS paysafecard e gioca senza rischi.

Na stronie Mostbet PL dostępne są atrakcyjne bonusy powitalne dla nowych graczy i stałych użytkowników.

Immer mehr Communities sprechen über sportwetten ohne oasis. Der Trend zeigt klar nach oben.