What we do at SS Metals & Industries?

Our Fabrication Services

Custom Welding

Quality Control

To ensure everything is correct with the custom metal fabrication projects we ship, we assemble them to the fullest extent possible before they leave our shop. This means two things: In the first place, we put together all assemblies and subassemblies to check that everything fits together as planned. While we’re doing this, we document everything and send photographs and paperwork to our customers to approve before shipping. Second, we ship assemblies and subassemblies in the most complete forms possible. For example, it’s rare that a huge tank will be able to ship fully assembled, so we send large subassemblies that are subsequently assembled on site. On the other hand, it usually isn’t a problem to ship fully assembled carts or ladders.Welding Machines

Our main welding process is MIG gas metal arc welding, but we also have TIG welders, stud welding machines, and portable welders we use on installation jobs.Customized Storage Tanks

Features:

- Sturdiness

- Anti-corrosive

- Finely finished

Specifications :

Material: MS 2062 Plate Thickness: Varies Between 5mm, 6mm, 8mm and 10mm. Capacities: Available Between 1KL to 500KL. Versions: Above Ground or Under Ground. Shapes: Cylindrical or Rectangular P.S: These are custom built products. So, the exact specs cannot be given.High Rise PEB Construction

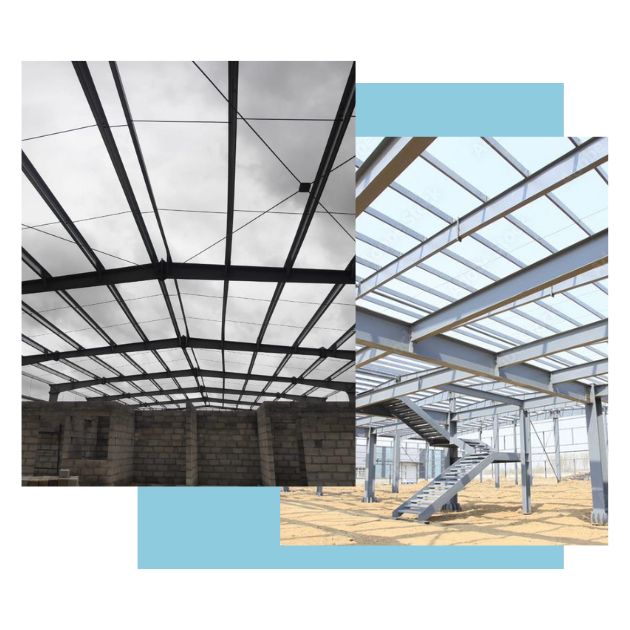

Pre-Engineered buildings or PEBs structure are made up of various components that give them their unique properties and make them sturdy and durable. Pre-Engineered Buildings are known for their flexible design, high structural strength and ease of construction. But all this is made possible due to the various components that go into building a PEB. Just like any assembled structure, a PEB consists of components that can be categorized into 3 main types and a few accessories.

A PEBs Structure (Pre-Engineered buildings) is made of: Primary Components Secondary Components Roofing or Cladding Other Accessories #1 – Primary Components: The Primary components include 3 main parts: Main Frame, Columns and Rafters. Main Frame: The main frame is the basic structure of the building which is made of rigid steel. It is built using tapered columns and rafters, sometimes also referred to as built-up members. There are spliced plates welded to the end of these tapered sections. The splice plates of connecting sections are bolted and the frame is erected. Columns: Columns are used to transfer the vertical load to the foundations. These are generally made up of I sections which give benefits in terms of strength while being economical to produce. Rafters: Rafters are sloped structural members or beams that extend from the ridge or up-to-the wall-plate.They are designed to support the roof deck and other loads associated with it. #2 – Secondary Components: Purlins, Bracings, Tie rods, Angle bracings, High Tensile Bolts and washers etc. are classified as secondary components that are used in a PEB. These parts are used to support walls and roof panels. In addition to that, the secondary members also help the building withstand the longitudinal loads that the building may see during earthquakes and heavy winds. Purlins are mostly unique cold roll-formed sections used to fix roof and side claddings. They are available in different variations such as Z, C and Sigma purlins which are denoted by their cross-section. #3 – Roofing or Cladding: Roofing sheets, as their name suggests,provide protection to the building interior from the environment. They can be designed to either block sunlight or allow partial sunlight to illuminate the interiors, depending on the requirement. A Standard supply of material for Roof Sheets is 0.47 mm Bare Galvalume and for wall Claddings it is 0.50mm Colour coated Galvalume. #4 – Other Accessories: Several accessories are available for Pre-Engineered Buildings or PEBs structure that can greatly increase the functionality of the building. Depending on the type of application, the accessories may be selected. Some of the many available accessories used in PEBs are Windows Turbo Ventilators Louvres Sliding Doors Roll-Up Shutters Skylight Sheets Ventilators DownspoutsPiping

- Stainless Steel Tank Fabrication

- SS Pipe Fabrication

- Steel Fabrication Companies

- Industrial Fabricators

- Fabrication Services

- Metal Fabrication

- Steel Fabrication Work

- Heavy Structural Fabrication

- Stainless Steel Fabrication

- Sheet Metal Fabrication

- Custom Stainless Steel Fabrication

- Custom Metal Fabrication

Road Tanker Service & Repairs

- Minor & Major Repairs

- Major Rollovers and Upgrades

- Refurbishments

- Hydrostatic Testing

- Safe Load Pass Inspections

- Engineering expertise

- New Decoking facilities for all Bitumen tankers

- Insurance claims

Sheet Metal Fabrication

- Doors

- Enclosures

- Body Panels

- Brackets

- Cones

- Bins

- Industrial Ductwork High Production Volume For Sheet Metal Fabrication There are times when you will require a very large production volume to fulfill your work order and maximize your profitability. SS Metals & industries is capable of producing thousands of units with reasonably short lead times and uses the latest technology.

PEB

High Rise PEB Construction

With continuous development and improvisation of processes comes efficiency, and cost effectiveness. When it comes to building structure construction PEB is the way to go. PEB has revolutionized the way builings are thought and built. They are cost effective, require less time to build and are modular.